One of the leading causes to batch failure in the Pharmaceutical Industry is contamination. These failures are extremely costly, resulting in lost sales, a redo of bioprocessing, studies to satisfy regulators, and other such problems. Electropolishing is critical to reducing contaminants in equipment used in the pharmaceutical industry. Electropolishing removes surface imperfections and contaminants from the metal, creating a microscopically smooth finish that helps to prevent the buildup of bacteria, dirt, oils, and chemical residue.

One of the leading causes to batch failure in the Pharmaceutical Industry is contamination. These failures are extremely costly, resulting in lost sales, a redo of bioprocessing, studies to satisfy regulators, and other such problems. Electropolishing is critical to reducing contaminants in equipment used in the pharmaceutical industry. Electropolishing removes surface imperfections and contaminants from the metal, creating a microscopically smooth finish that helps to prevent the buildup of bacteria, dirt, oils, and chemical residue.

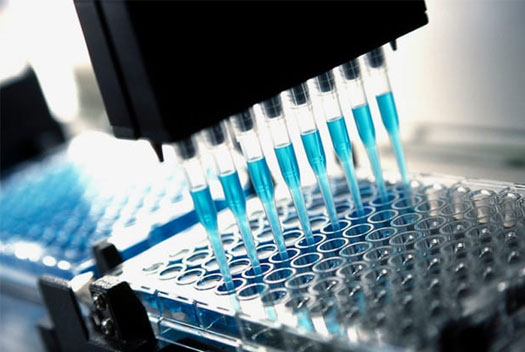

Surface finish is incredibly important for high purity systems in pharmaceutical equipment since hygiene is of utmost importance when processing and manufacturing pharmaceutical products. The surface of metal parts in pharmaceutical equipment, including tanks, vessels, valves, pumps and other accessories needs to be perfectly smooth, free of anomalies and other contaminants left behind by mechanical polishing. Electropolishing is one of the most popular finishes for pharmaceutical applications and provides several crucial benefits.

Benefits of Electropolishing of Stainless Steel to the Pharmaceutical Industry:

- Produces an oxygen-rich, protective layer that is resistant to corrosion and is perfect for conditions such as blending pharmaceuticals.

- Diminishes product adhesion.

- Decreases friction and helps wipe out build-up which can slow down production.

- Leads to a clean and sterile surface, making it an ideal solution for the pharmaceutical and food industries.

ASME BPE Standard of Electropolishing

The American Society of Mechanical Engineers (ASME) provides a set of standards for the manufacturing and finishing of bioprocessing equipment. These standards, known collectively as ASME BPE, ensure the high quality and continued safety of parts used in pharmaceutical, bioprocessing and other industries that require superior hygiene and performance capabilities.

| Surface | Ra Max. I.D. | Polishing | |

| Disignation | µin. | µm | Criteria |

| SF0 | No Finish Requirement | ||

| SF1 | 20 | 0.51 | Mechanically Polished |

| SF2 | 25 | 0.64 | Mechanically Polished |

| SF3 | 30 | 0.76 | Mechanically Polished |

| SF4 | 15 | 0.38 | Mechanically Polished and Electropolished |

| SF5 | 20 | 0.51 | Mechanically Polished and Electropolished |

| SF6 | 25 | 0.64 | Mechanically Polished and Electropolished |

Shop and Field Services Available

Allegheny Surface Technology offers both shop services and field services depending on your need. AST has the capacity to electropolish stainless steel and high nickel alloy components of all sizes at our 24,000 square foot facility or at any job site as if we were bringing our shop to you. We understand how important it is to get your equipment back up and running. Equipment failure means downtime resulting in dollars lost. Our specialized field service technicians perform the work at your site in the timeliest manner possible. Our turnkey field services include: electropolishing, mechanical polishing, citric passivation, complete vessel refurbishment, ASME code welding, vessel assessment, level II inspection, liquid dye penetrant testing, surface measurement readings, and borescope inspections. All necessary inspections and tests are performed and documented. Our procedures for all services are recognized by and in compliance with the ASME-BPE standards.