Benefits of Pickling

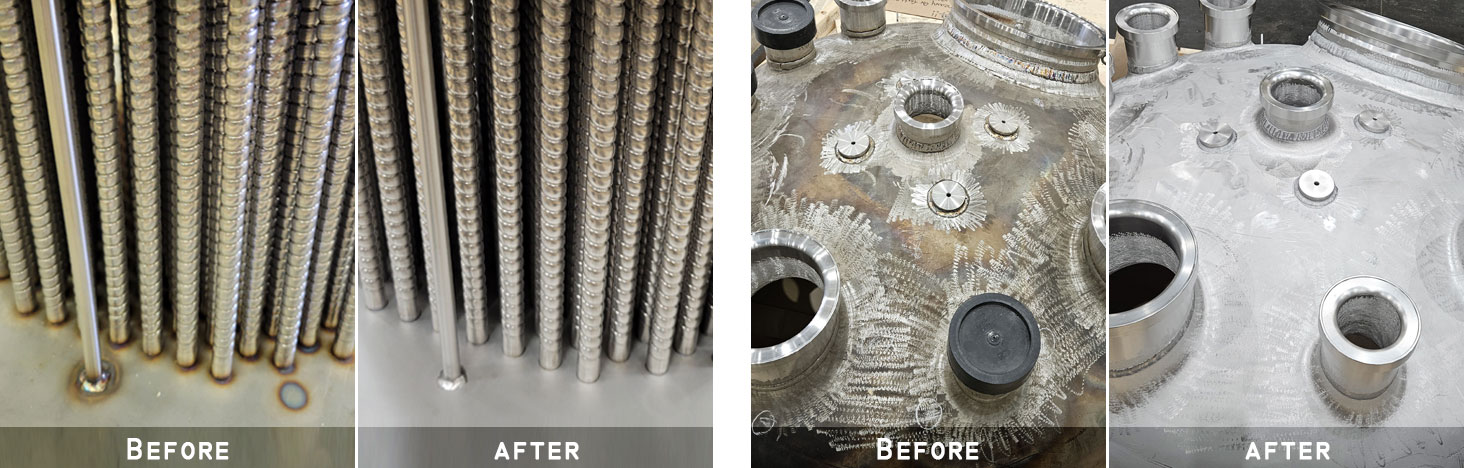

Pickling is a chemical process that is commonly used to remove scale, discoloration, and oxide layers that form on the surface of stainless steel during the manufacturing process. These impurities can affect the appearance, corrosion resistance, and overall quality of the stainless steel. By eliminating these contaminants, pickling enhances the performance and longevity of stainless steel products.

Increased Corrosion Resistance

One of the major advantages of stainless steel pickling is the increased corrosion resistance it provides. When stainless steel is exposed to oxygen, moisture, or corrosive substances, it can develop rust or corrosion. The pickling process removes the surface contaminants that can accelerate corrosion, allowing the stainless steel to maintain its integrity and performance even in harsh environments. By pickling stainless steel, industries can ensure that their products have a longer lifespan and are better equipped to withstand the test of time.

In addition, pickling enhances the passivation process of stainless steel, creating a protective layer on the surface. This protective layer acts as a barrier, preventing the corrosive agents from reaching the underlying metal. As a result, the stainless steel remains resistant to corrosion, even when exposed to aggressive substances or conditions.

Improved Cleanliness

Another benefit of stainless steel pickling is the improved cleanliness. Surface contaminants, such as dirt, grease, or fingerprints, can accumulate on stainless steel surfaces during handling or storage. These contaminants can contribute to the degradation of the stainless steel and compromise its performance. By pickling the stainless steel, these contaminants are thoroughly removed, ensuring a clean and pristine surface.

Removal of Surface Contaminants

Stainless steel pickling is highly effective in removing surface contaminants from the material. During the manufacturing process, stainless steel can accumulate impurities, such as dirt, scale, oil, or rust. These contaminants can compromise the quality and performance of the stainless steel, leading to corrosion, reduced lifespan, or inferior aesthetics.

By pickling the stainless steel, these surface contaminants are chemically dissolved and removed, leaving behind a clean and pure surface. This ensures that the stainless steel is free from any impurities that could affect its properties or appearance. As a result, the pickled stainless steel is of higher quality and better suited for various applications, from food processing equipment to architectural structures.

Enhanced Weldability

Stainless steel pickling also improves the weldability of the material. Welding is a commonly used process in the fabrication of stainless steel products, but it can introduce impurities, such as heat tint or oxides, that can compromise the integrity of the weld joint. These impurities can lead to reduced corrosion resistance, poor aesthetics, or even structural defects.

By pickling the stainless steel prior to welding, these impurities are effectively removed, ensuring a clean and contaminant-free surface. This allows for a stronger and more reliable weld joint, with improved corrosion resistance and aesthetics. As a result, pickled stainless steel is widely preferred in industries that require high-quality welded stainless steel products, such as automotive, aerospace, or pharmaceutical.

Extended Lifespan of Stainless Steel

Perhaps one of the most significant benefits of stainless steel pickling is the extended lifespan it provides to the material. Stainless steel is known for its durability and resistance to corrosion, but without proper maintenance and surface treatment, it can still degrade over time. Surface contaminants, such as scale, oxide layers, or dirt, can accelerate the corrosion process and compromise the structural integrity of the stainless steel.

By pickling the stainless steel, these surface contaminants are effectively removed, allowing the material to maintain its corrosion resistance and durability for a longer period. The pickling process also enhances the passivation of stainless steel, creating a protective layer that acts as a barrier against corrosive agents. This further extends the lifespan of the stainless steel, making it a cost-effective and reliable choice for various applications.