Why is Passivation Necessary?

Manufacturing stainless steel parts begins with fabrication or machining. All parts must be made to particular specifications and follow the guidelines of design and application. Once fabrication or machining is complete, parts are likely to have with free iron and other foreign material embedded in the surface.

Why it matters: As the final step, passivation is crucial because it ensures the corrosion resistance of stainless steel parts. The successful establishment of corrosion resistance on a critical part ensures long, efficient service of the part or vessel in whatever process it’s used in. Whereas failure to do this correctly leads to corrosion, reduced efficiency and ultimately, reduced lifespan of the part. Altogether, these factors can increase costs significantly.

What is Passivation?

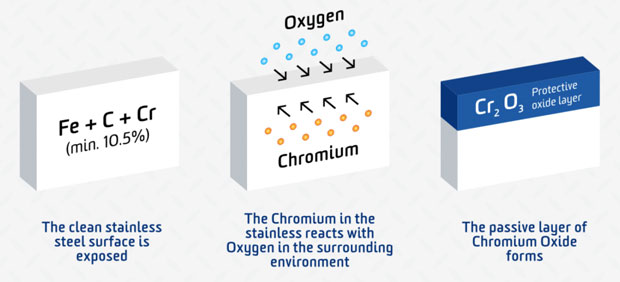

Passivation is a combination process – part cleaning and part protective – that creates a passive layer on a stainless steel surface. This layer protects the metal from selective oxidation or corrosion.

Specifically, passivation is a chemical process involving a mild oxidant, such as a nitric acid solution, that removes “exogenous iron or iron compounds from the surface of stainless steel by means of a chemical dissolution…that will remove the surface contamination, but will not significantly affect the stainless steel itself…for the purpose of enhancing the spontaneous formation of the protective passive film,” according to ASTM A380.

The passivation process removes what’s known as “free iron” contamination. While this contamination is a normal in the machining and fabricating process for any stainless steel part, such contamination areas are also potential corrosion sites. If left in place, they will result in premature corrosion and deterioration of the part.

This is where the passivation process as a finishing step – or a routine maintenance step – becomes critical to the life and usefulness of every stainless steel part.

Why is Passivation Necessary?

Our customers will often ask if passivation is necessary. If the interest is in achieving the longest life and the best operation of a component in a manufacturing process, the answer is “yes.”

Even though the definition of passivation focuses on removing the “free iron” contamination, stainless steel components typically also acquire areas of grease, oil, and other substances on their surfaces during manufacturing. Moreover, microscopic particles of shop dirt or iron from cutting tools can become embedded in the surface of the stainless steel parts during machining. These foreign particles impair the integrity of the original protective layer. Passivation cleans away these contaminants and creates the necessary passive layer, providing the best possible corrosion resistance.

How is Stainless Steel Passivation Done?

The first step of the passivation process involves cleaning the parts to prepare them for the solution. This step removes grease, dirt, dust and other surface contaminants.

Then comes the oxidizer or “acid dip” stage. Each job is different. So success at this stage requires deep knowledge of the chemistry of the acid mixture and other aspects of the process. These include which acid recipe works best for each situation, the ideal temperature, optimum duration of the bath, and how to adjust each of these factors based on the materials treated. When all of these factors are aligned into an ideal process, all free iron is removed from the surface, allowing the formation of an evenly-distributed oxide layer.

A thorough rinse in clean water is the final step.

How is Passivation Validated?

Ensuring a successful stainless steel passivation process is achieved through testing and validation.

This final step assures the effectiveness of the passivation process and most importantly, certifies compliance with ASTM, Mil-Spec, and other industry standards.

When additional assurance is required for specific processes, parts are further tested using methods such as high humidity, salt spray, water immersion, and ferroxyl testing. Such measures are particularly important for complex, highly-regulated industries and applications like aerospace, medical, military, and other areas where high reliability or safety are critical.

Is Passivation a One-Time Only Process?

No. Parts need to be re-passivated as a part of routine maintenance, depending on the service of the part. Factors include the demands of its processing conditions and how aggressive the chemicals are for processing and cleaning. Remember: experts who specialize in passivation are your best guide in helping you assess the best process for the specific needs of your parts – and your process.

Allegheny Surface Technology is an industry leader in passivation services, delivering high quality services to our customers. Request a quote or call us to speak to a specialist about stainless steel passivation today.

Allegheny Surface Technology is your trusted provider of high-performance, ASTM and BPE compliant electropolishing, pickling, mechanical polishing, and passivation services. Specializing in both in-house and on-site stainless steel surface refinishing/refurbishment services, AST assures both the quality and reliability of our services through multi-step Quality Assurance and inspection protocols.